+86 183 6377 3366

+86 183 6377 3366 News Categories

Featured News

0102030405

Corning Unveils Lightweight Pharmaceutical Glass Vials at CPHI Frankfurt: 20% Material Reduction Achieves 30% Emission Cut, Reshaping Pharmaceutical Packaging Standards

2025-11-26

Core Breakthrough: Two-Way Balance Between Safety and Environmental Protection

The lightweighting of pharmaceutical Glass has long been constrained by two major challenges: "strength compromise" and "drug compatibility". Corning has achieved breakthroughs through three major technological innovations:

Material formula upgrade is the core competitiveness of the product. The Viridian® series adopts a modified borosilicate glass formula. By adjusting the ratio of silica to boron oxide, it reduces glass usage by 20% while increasing impact strength by 15%, meeting the strict breakage resistance requirements of the United States Pharmacopeia (USP) for pharmaceutical glass. To meet the stability requirements of biological agents, the inner wall of the vial is specially coated to effectively inhibit glass delamination, and its drug compatibility is equivalent to Corning's classic Valor® glass .

Precision molding technology further releases environmental potential. The adopted "near-net shaping" technology reduces waste generation during glass processing, and combined with an automated inspection system, the product qualification rate is increased to 99.8%. Production data shows that the weight of a single 20ml Viridian® vial is reduced from 12g of traditional products to 9.6g. Based on the global annual demand of 5 billion vials, it can save 1,200 tons of glass raw materials annually, equivalent to reducing 18,000 tons of carbon dioxide emissions.

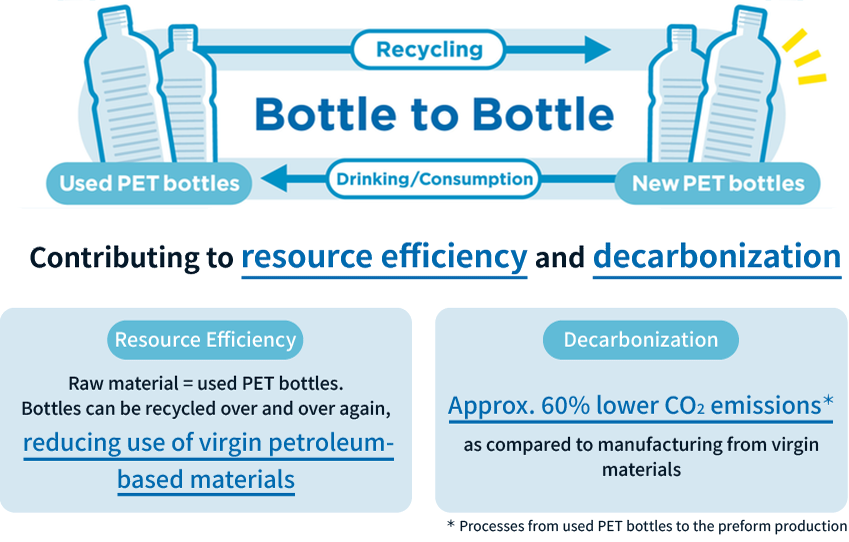

Full-chain emission reduction design forms an environmental closed loop. Corning has simultaneously optimized packaging and logistics solutions, using recyclable polypropylene pallets instead of traditional cartons. Combined with the lightweight vial design, the transportation carbon emissions of each batch of goods are reduced by 25%. The product also supports "bottle-to-bottle" recycling, with a cullet recycling rate of up to 95%, perfectly adapting to the ESG strategic needs of pharmaceutical companies.

Market Prospects and Industry Transformation

Corning plans to launch mass production of the Viridian® series in the second quarter of 2026. Initially, it will launch three specifications of 10ml, 20ml, and 50ml, all providing ready-to-use (RTU) sterile packaging, suitable for the production of high-end preparations such as vaccines and monoclonal antibody drugs. According to the market forecast of IMARC Group, with the growing demand for sustainable packaging in the global pharmaceutical industry, the lightweight pharmaceutical glass market will expand at a CAGR of 11.2%. Corning is expected to occupy more than 35% of the market share with its technological first-mover advantage .

This innovation will further drive the upgrading of pharmaceutical packaging industry standards. Jennifer Cook, Vice President of Corning's Pharmaceutical Technologies Division, stated: "The launch of Viridian® proves that pharmaceutical glass does not need to compromise between safety and environmental protection. Our goal is to reduce the average carbon footprint of global pharmaceutical glass packaging by 25% by 2030." The procurement intentions reached on-site show that the first batch of products will be prioritized for Pfizer's vaccine production lines and Roche's biological agent packaging, expected to replace more than 300 million traditional glass vials annually.