+86 183 6377 3366

+86 183 6377 3366 News Categories

Featured News

0102030405

TOYO GLASS Launches "Super Ecology Bottle": 90% Mixed-Color Cullet Enables Infinite Recycling, Reshaping Japan's Packaging Environmental Standards

2025-11-26

Technological Innovation: Solving the Dilemma of Mixed-Color Cullet Recycling

The core breakthrough of the "Super Ecology Bottle" lies in overcoming two major industry pain points in mixed-color cullet recycling—uneven color and insufficient strength, with its technological innovations reflected in three dimensions:

In terms of formula optimization, the proprietary clarifying agent developed by TOYO GLASS can effectively neutralize impurity ions in mixed-color cullet. Even when using recycled materials containing multiple colors such as green and blue, it can still produce Glass Bottles with a transparency of 85%, solving the problem of turbid color in products made from traditional mixed recycled materials. According to testing by the Japan Glass Bottle Association, the impact resistance and internal pressure resistance of this product meet the JIS Class 1 standard, which is identical to glass bottles made from virgin materials .

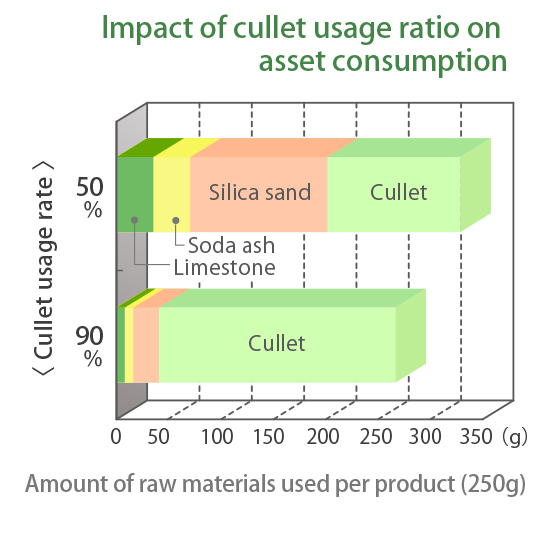

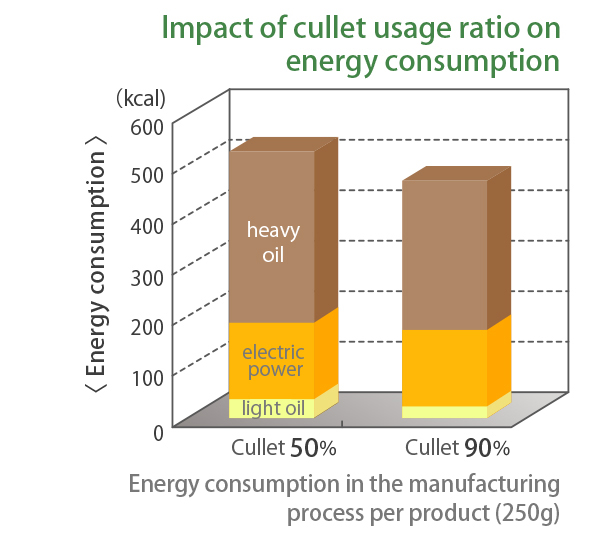

In terms of energy conservation and carbon reduction, the use of high-proportion cullet brings significant environmental benefits. Data shows that for every 10% increase in cullet usage, the thermal efficiency in the glass melting stage can be improved by approximately 2.5%. The 90% cullet ratio of the "Super Ecology Bottle" reduces energy consumption in the production process by 22.5%, and correspondingly reduces emissions of pollutants such as carbon dioxide and sulfur dioxide by more than 30%. This indicator far exceeds the basic requirements of Japan's "Containers and Packaging Recycling Law", setting a new environmental benchmark for the industry .

In terms of recycling system adaptation, the product is specifically designed for Japan's recycling situation and can directly utilize mixed-color cullet classified as "other" in the existing recycling network. Previously, such cullet often faced inventory backlogs due to low utilization rates, while the mass production of the "Super Ecology Bottle" will effectively absorb the existing waste materials, expected to reduce the amount of glass waste landfilled in Japan by more than 50,000 tons annually.

Market Implementation and Industry Impact

TOYO GLASS plans to launch large-scale production of the "Super Ecology Bottle" in March 2026, with an initial production capacity of 12 million units per month, prioritizing supply to Japan's sake, fruit juice, and condiment industries. It has already reached cooperation with well-known brands such as Kikumasamune Sake and Kagome, and the first 600ml sake bottle product will carry the "Ecology Bottle Certification Mark". The premium of terminal products is expected to be controlled within 5%, balancing environmental value and market acceptance.

This innovation has further promoted the formation of a synergy in Japan's glass packaging industry. A responsible person from Suntory Group's sustainable development department stated that its "bottle-to-bottle" recycling system will prioritize adaptation to the "Super Ecology Bottle" to further improve recycling efficiency through technological complementarity. Kenichi Matsumoto, President of TOYO GLASS, pointed out: "The efficient utilization of mixed-color cullet is the final piece of the puzzle in the glass circular economy. Our technology turns 'infinite recycling' from a concept into reality, and is expected to drive Japan's overall glass packaging recycling rate from the current 78% to 90% by 2030."